Paint Booth Paint Spray Booth Paint Oven with Infrared Heating System

Guangzhou Infitech Mechanical and Electrical Equipment Co., Ltd.- After-sales Service:24 Hours After Service

- Warranty:2 Years

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Brand:Infitech

Base Info

- Model NO.:IT-701

- Coating:Powder Coating

- Airflow Direction:Fully Undershot-type

- Heating Mode:Infrared Ray

- Paint Mist Treatment:Dry-type

- Condition:New

- Empty Loaded Air Speed:+,-0.28m,S

- Voltage:380V, Your Special Voltage Is Accepted.

- Fan Capacity:28000m3,H

- Transport Package:Polyfoam and Metal Frame

- Specification:7000MM X 4000MM X 2800MM (LXWXH)

- Trademark:INFITECH

- Origin:China

- HS Code:8419899090

- Production Capacity:300 Sets Per Year

Description

BS EN 60204: 2006 + A1: 2009

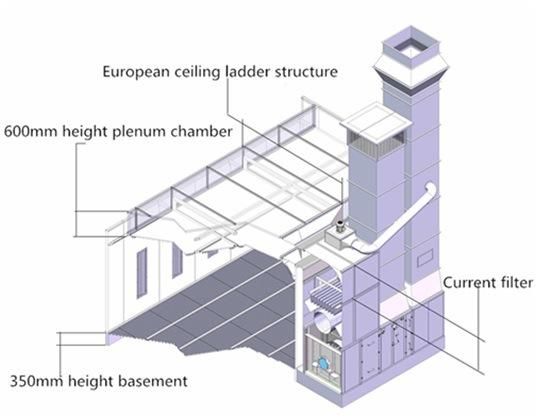

Basement(H): 350mm and can be adjustable

Detailed information

- Entrance door

Door size: 3200X2700(BXH) observation window size: 1995X500(BXH)

- Cabin structure

After the air flow goes through the heat exchanger rapidly, it will then pass through the diffuser, which provides important assistance to form the balanced and stable air distribution in the plenum.

The balanced airflow formed around the vehicle is achieved by the 350mm height basement. There is reasonable and effective diversion device for the basement, which helps to balance the airflow from end to end.

- Rock Wool Board

- Top plates: Double insulation board filled with 80KG/m³ rock wool, total thickness: 50mm, substrate thickness: 0.426mm

The panels are made of double galvanized steel plate with complementary treatment of five coats of paint (polyester, acrylic and silicone polyester heat-hardened with plastic film for added protection) on each side.

- Lighting system

- IP55 protection grade, light fixtures fully meet EU standards.

- Basement

- Plug-in type grid structure, full grids, safe and reliable

- Fiber-glass paint-stop filter (laid under the grids), G2 grade, paint holding capacity: 3.5KG/m2

- Airflow system

- Motor and fan are completely separated, which is compulsory requirement for fans in EN13355-2004.

- Adopting cylinder-drive paint-bake conversion damper, more quickly and accurately.

- Filtration system

- Control system

- Warm painting

- Baking

- Lighting

- Emergency stop switch

- Failure stop switch

- Failure indication

- Dual-channel over-temperature protection

- PLC intelligent control

- Electric pressure balancing system

- Self-diagnostic fault

Main optional components: SIEMENS, OMRON, etc.

Infrared ray heating system

1) Infrared ray lamps

- Total 10 units of IR heating boxes (4 units on the left, 4 units on the right, 2 units on the back)

- Power: 3 x 1kW/unit, size: 585 x 80 x 500MM per set

- Each light box has 3pcs X 21 inches shortwave infrared lamps.

- The service time of the lamps can last as long as 5000 hours.

- Each box has a door, which keeps lamps off paint in painting phase. When it is in baking phase, the doors are opened.

- The lamps cannot work when doors are closed, which is achieved by 2 protective sensors set on the doors.

2) Control system

Microcomputer control system, touch button for the panel, stable and convenient to use.

3) Temperature control

When it reaches the setting temperature the heating system stops working automatically; when the temperature falls down below the setting temperature, the heating system starts working automatically.

4) Time control

The baking time can be set in advance. When the setting time is up, the heating system stops working automatically.

5) Group control

Total power is 30KW, controlled in 10 groups, 3KW per group. One group works individually or 10 groups work all together.

6) Power adjustment

The control box is installed with silicon controlled rectifier, which can adjust the heating power. When electricity power is not enough or no need to increase the temperature quickly, the operating power of the lamps can be turned down (10KW - 30KW).

7) Automatic slow start function

When the heating system is working, the silicon controlled rectifier is triggered slowly by the interior trigger of the temperature control system, which makes the infrared ray heating lamp work slowly, lessening the impact on the power system.

Factory image:

Packing and loading:

Please feel free to contact us if any inquiries. Thank you.