Customized Wheel Rims Forged Aluminum Alloy Wheels Rims, 17 18 19 20 21 22 Inches

Ningbo Kangyang Technology Co., Ltd.- After-sales Service:1 Year

- Warranty:1 Year

- Material:Aluminum

- Type:Wheel Hub

- Drive Wheel:RWD

- Wheel Hub Diameter:16inch-22inch

Base Info

- Model NO.:L-CFW-014

- Finishing:Poweder Finish

- Wheel Accessories:Wheel Cover

- Spoke Type:Equal Diameter Spoke

- Certification:ISO, VIA, CE, TUV, DOT

- Wheel Hub Brand:Lda or Custom Logo

- Transport Package:Each Wheel Per Carton

- Specification:depends on size

- Trademark:LDA or Custom Logo

- Origin:China

- HS Code:8708709100

- Production Capacity:25000 PCS Per Year

Description

L-CFW-00115 days

Step one : Forging

The forged wheel is created from a T6 heated aluminium 6061,which in its turn, it pressed at different

steps by an 12000 t press.thus the wheel develop its rough cylindrical shape.

The Channiel is then stretched using the spinning process, which is a technology to streth the material

in the same direction, which makes molecular stracture of the wheel more average and stable, and stronger.

Which lead the wheel safer and support of the working loads

After spinning Process, the blank forged wheel is putting in the equipment for heat treatment.

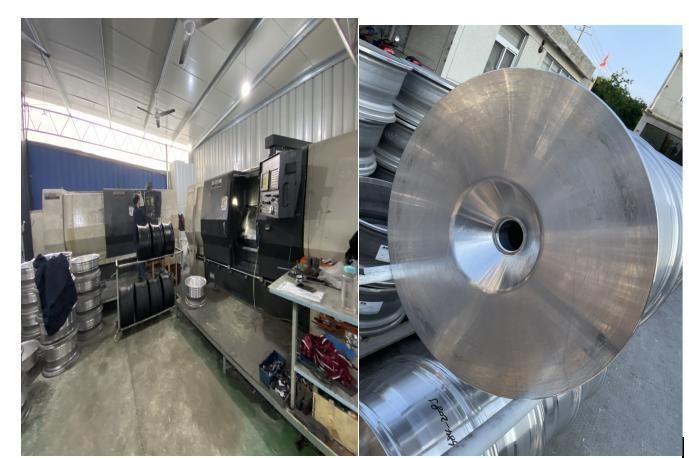

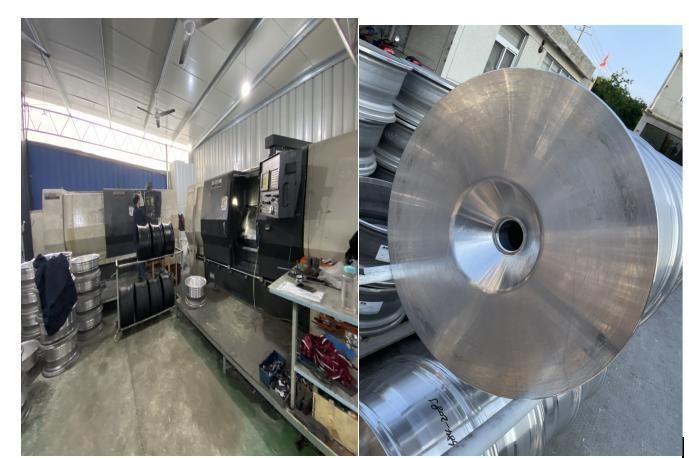

Step 2 :Turnning Machine Work

We Turnning Machine the Forged Blank to the BLank Wheel as below to Ready Different Design

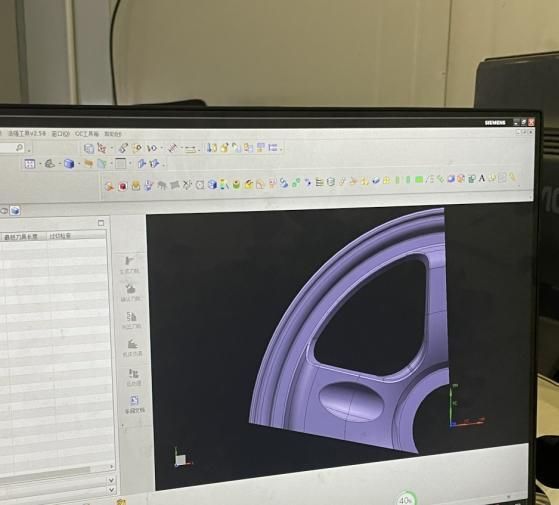

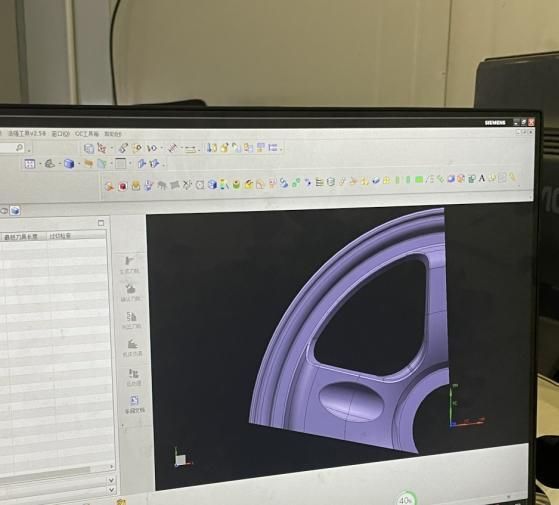

Step 3: Design and Project

LDA Forged wheels are designed using the most modern 3D , CAD/CAM design software

LDA Forged wheels are designed using the most modern 3D , CAD/CAM design software

and FEM analysis ( finite Elemet Analysis).

From the First drawing, to 3d graphics , from 0 to finished wheels.

All the wheels are designed on the basis of differnt model of car. From European Model,

USA Model, Japan Model, Korean Model and China Model

Step 4: Mechinaical CNC WORK

Professional Lathes provides the forged wheel perfect roundness, runout and Balance. The high-precision

CNC work station make the forged wheel perfect axial alignment with the channel, with significantly keep

the wheel surface looks high gloss and fantastic surface.

Step 5 : Surface Option: Poweder , Polish, Brush and Chrome

We can do Poweder, Polish, Brush and Chrome finish for our customers to fit out customer different requirement

Powerder Finish

Chrome Finish

Chrome Finish

Step 6: Finish Wheel

Packaging & Shipping

Packaging & Shipping

We have made 6 layers of packaging to protect the wheels from any damage:

1. Plastic film is used as the basic protection to protect the wheel barrel from rubbing.

2. Sponge protective film protects the wheel's spokes from scratching.

3. The dust cover protects the wheel's spokes from dust.

4. The plastic bag is packaged as a whole to protect the entire wheel from any dust.

5. The overall packaging of bubble film protects the wheel from any bumps.

6. Final wheel carton packaging

Sea Port

Ningbo or Shanghai

Lead Time:

Step one : Forging

The forged wheel is created from a T6 heated aluminium 6061,which in its turn, it pressed at different

steps by an 12000 t press.thus the wheel develop its rough cylindrical shape.

The Channiel is then stretched using the spinning process, which is a technology to streth the material

in the same direction, which makes molecular stracture of the wheel more average and stable, and stronger.

Which lead the wheel safer and support of the working loads

After spinning Process, the blank forged wheel is putting in the equipment for heat treatment.

Step 2 :Turnning Machine Work

We Turnning Machine the Forged Blank to the BLank Wheel as below to Ready Different Design

Step 3: Design and Project

LDA Forged wheels are designed using the most modern 3D , CAD/CAM design software

LDA Forged wheels are designed using the most modern 3D , CAD/CAM design softwareand FEM analysis ( finite Elemet Analysis).

From the First drawing, to 3d graphics , from 0 to finished wheels.

All the wheels are designed on the basis of differnt model of car. From European Model,

USA Model, Japan Model, Korean Model and China Model

Step 4: Mechinaical CNC WORK

Professional Lathes provides the forged wheel perfect roundness, runout and Balance. The high-precision

CNC work station make the forged wheel perfect axial alignment with the channel, with significantly keep

the wheel surface looks high gloss and fantastic surface.

Step 5 : Surface Option: Poweder , Polish, Brush and Chrome

We can do Poweder, Polish, Brush and Chrome finish for our customers to fit out customer different requirement

Powerder Finish

Chrome Finish

Chrome Finish

Step 6: Finish Wheel

Packaging & Shipping

Packaging & ShippingWe have made 6 layers of packaging to protect the wheels from any damage:

1. Plastic film is used as the basic protection to protect the wheel barrel from rubbing.

2. Sponge protective film protects the wheel's spokes from scratching.

3. The dust cover protects the wheel's spokes from dust.

4. The plastic bag is packaged as a whole to protect the entire wheel from any dust.

5. The overall packaging of bubble film protects the wheel from any bumps.

6. Final wheel carton packaging

Sea Port

Ningbo or Shanghai

Lead Time:

| Quantity(Pieces) | 1 - 4 | >4 |

| Est. Time(days) | 15 | To be negotiated |